4th year student Alexa Brett is working on a new collaborative project with the humanitarian charity HoverAid to improve the design of the hovercraft that they use to reach remote communities.

This is an incredibly interesting 4th year project that I’m delighted to be working on. It’s combining my interest in aerodynamics and vehicle propulsion with the worthy cause championed by HoverAid.

Alexa Brett

HoverAid provides medical care, community health programmes, and emergency relief to isolated communities, currently primarily in Madagascar. They use hovercraft and other means to bring aid and development to those in need. HoverAid also provide cost-effective access for partner organisations, enabling them to do what they do best in communities that need help and support the most.

Andy Mayo, Chief Development and Technical Officer at HoverAid, caught up with Alexa over a socially distanced coffee to find out how the project is going.

Andy: It’s great that the University is getting involved; as a student what interests you about the project, and why did you choose HoverAid for your 4th year project?

Alexa: The project is pretty unique in the Department of Engineering as it offers the opportunity to investigate and design something that makes a genuine difference to people’s lives rather than making very small improvements to industrial designs or undertaking niche research. This is on top of the “wow factor” working on hovercraft entails. Combining all of this is making it an incredibly interesting 4th year project that I’m delighted to be working on. It’s combining my interest in aerodynamics and vehicle propulsion with HoverAid's worthy cause.

Andy: That’s fantastic, and what are you hoping to learn?

Alexa: We’re hoping to be able to provide a significant amount of guidance on the design of the propulsion systems for the hovercraft. We effectively have propellers sitting inside cylinders, or ducts, with one on each side of the rear of the craft, to channel airflow. Then there are the flaps behind the fans to let the driver manoeuvre the craft like the rudder on a boat, with additional control in the vertical direction to allow the lifting or pushing down of each side of the hovercraft. By investigating the shape of these ducts, and trying to find an optimal design to produce more forward thrust, and increase efficiency, we can help. The shape is dependent on the conditions that the hovercraft operates in which could be heat or it could be the humidity of the rainy season or the altitude where the hovercraft are being used. The ultimate goal of the project is a program into which HoverAid can simply enter where they want to go and those associated conditions, and a design will be produced that can be 3D printed…possibly even on-site in Madagascar.

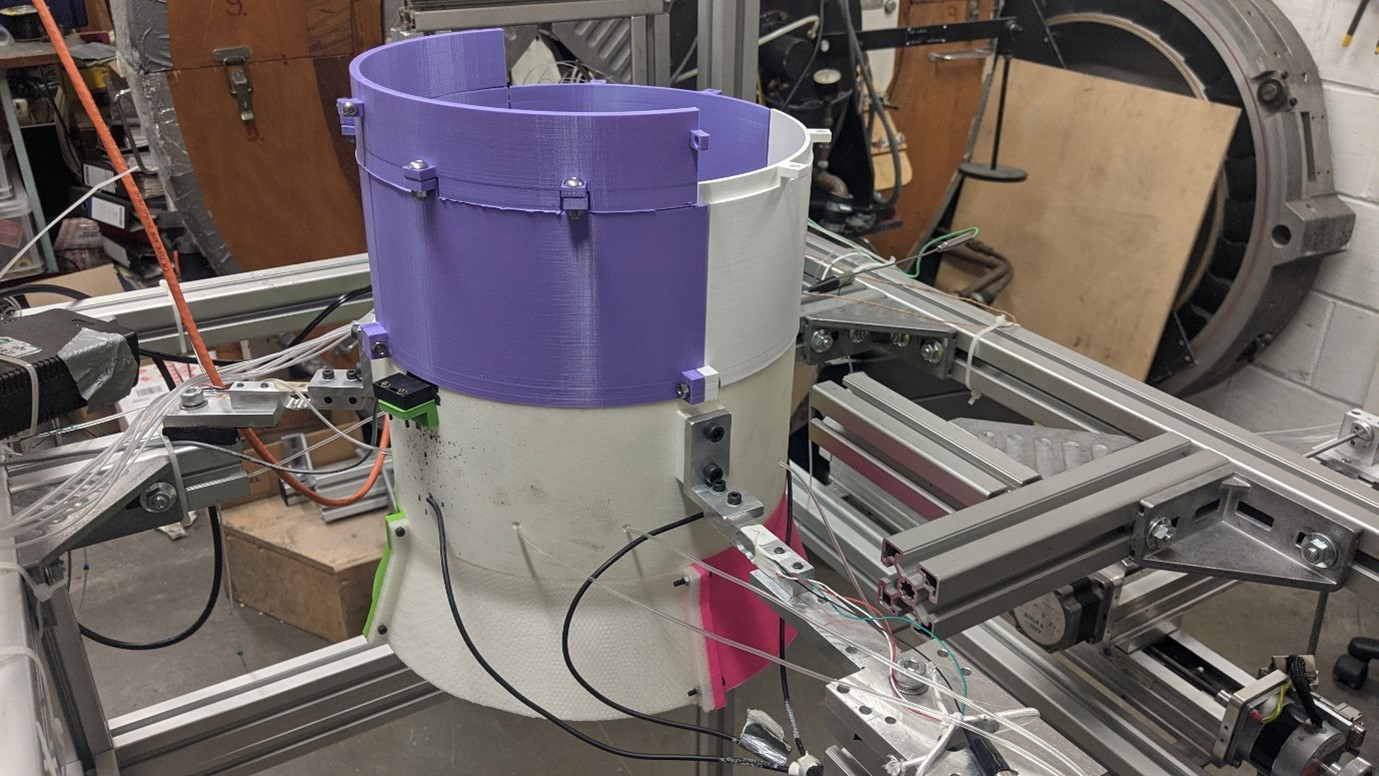

The test rig made in our workshop that Alexa is using for power measurements on the different duct designs

Andy: So is there anything interesting you’ve already concluded or discovered?

Alexa: We’ve already made significant progress using a test rig which allows power measurements, and we have been 3D printing test propulsion systems and running them since the start of November. We have proposed some design changes to improve it in front of the propellers, with lots more potential changes identified and coming soon!

Andy: We are incredibly grateful to you and Cambridge University, we’ll catch up with you as the project progresses through the year.

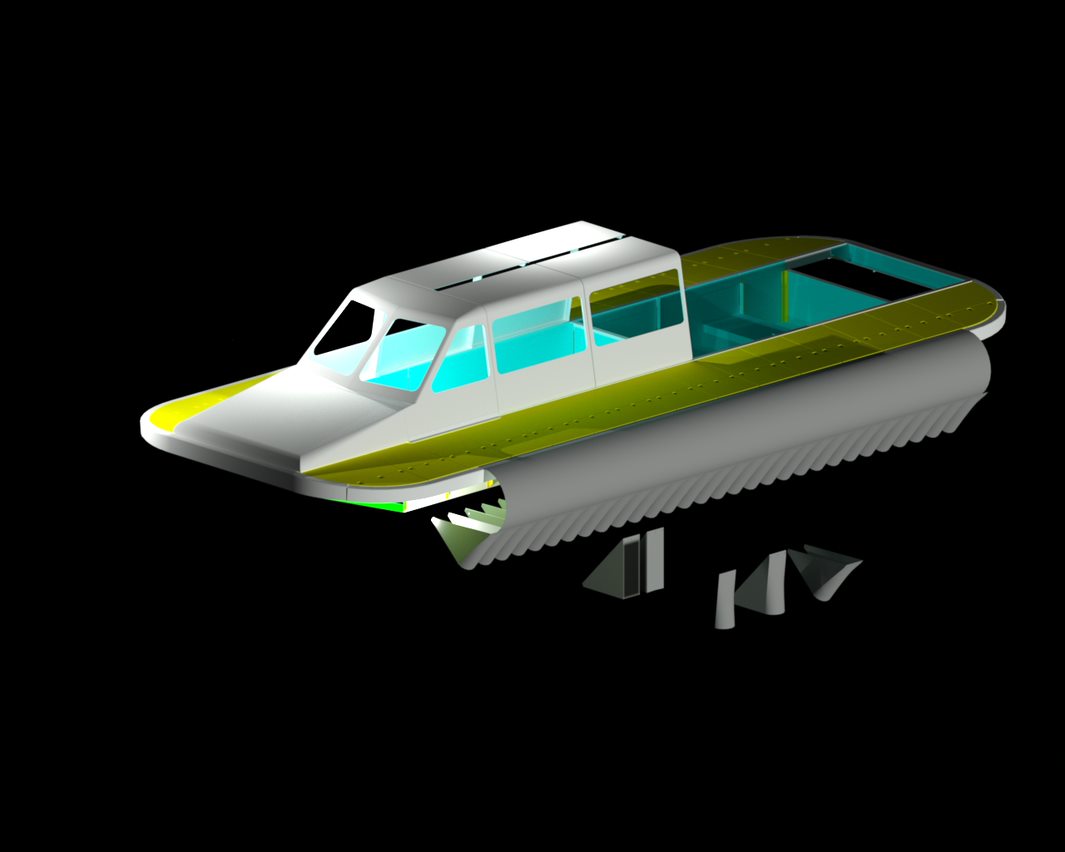

The "skirt" is the hardest part of the hovercraft to capture on CAD

Developing the hovercraft

Alexa's project will contribute to HoverAid's overall new hovercraft development programme. At this time Computer Aided Design (CAD) work to capture the design of their current "RiverRover" craft and make improvements is close to completion. The new design will be built in 2021.

One of the most complicated parts is the skirt – the rubber curtain that sits under the craft and captures the air that gives a hovercraft its unique ability to hover.

Getting the geometry of this right is critical to enabling the hovercraft to hover, turn, and maintain clearance over rocks, weeds, reeds, mud and sand. This takes serious computing power doing hundreds of thousands of iterations to home-in on the right solution.

Alexa's project is complementary to this work. There are a number of further potential 4th year projects on different aspects of the hovercraft, which HoverAid and the Department of Engineering are hoping to confirm alongside increased future collaborations.

Meanwhile, John Greaves, Chief Executive Officer of HoverAid is grateful to Alexa, her tutor Will Graham, and the Department for helping HoverAid improve tomorrow’s hovercraft fleet. John himself has recently been working in the Department on REF Impact assessments, as well as being an alumnus (MA Engineering; Trinity Hall 1978).

Find out more about HoverAid's work and how you can get involved via their website, follow them on Facebook or email John Greaves at j.greaves@hoveraid.co.uk