First prize

Steve Hoath

'Tails from the nozzle bank'

The winning image in the Epson Photography Competition recently held at the Department of Engineering, was taken by Dr Steve Hoath. Steve will receive the first prize of a Epson printer that has been generously donated by Epson.

This was taken with a Nikon D70 with a Navitar zoom macro lens and a very short flash duration (20 ns) light source. This image was taken during a series of experiments at the Cambridge Engineering Department, Inkjet Research Centre investigating the performance of inkjet printers. It shows ink drops emerging from a bank of inkjet nozzles (just visible at the bottom of the picture). The image is about 2.3 mm across, the drop heads are 50 microns across and the tails are less than 10 microns wide (10 times thinner than a human hair). Although very small the drops are moving at around 6 m/s hence the need for a very short flash to freeze the motion. The drops are in three groups with slightly different drop firing times. In some cases the drops are still attached to the nozzles by long ligaments of stretching liquid. Other drops show separation and the formation of smaller, “satellite” drops from the collapsing ligaments. This image was adjusted for brightness and contrast and rotated for effect.

Second prize

Laura Harrison

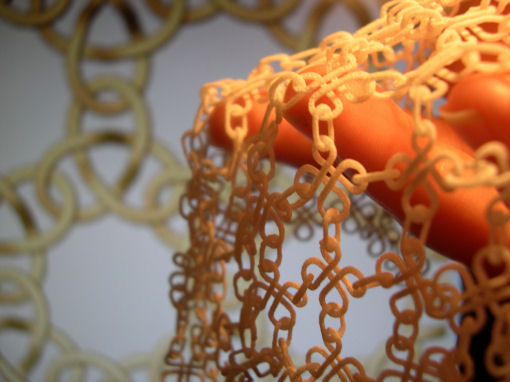

'untitled'

The photo that has won second prize, was taken by Laura Harrison, a 4th year MET student at the Department's Institute for Manufacturing (IfM). Laura will receive the second prize of an Epson Stylus Photo R800 desktop photo printer that has been generously donated by Epson.

Laura's photo is of prototypes of elastic chain-link designs. These designs are part of her fourth year project within the Production Processes group, investigating the potential for using 'Selective Laser Sintering' processes to produce textile structures, as part of wider research to establish new garment manufacturing techniques. A chain-link structure enables the creation of flexible textile structures from rigid materials, whilst related projects within the IfM are investigating the possibility of using biological materials such as silk to allow the creation of fibrous Rapid Manufacturing materials. The elasticity of the nylon used for this prototype can also be exploited to create links which stretch under an applied force.

This photo was taken with a Nikon Coolpix 4300 digital camera. The image shows the draping ability of a prototyped elastic chain-link design by fellow student Tania Thompson. The background image is a Solidworks model of a further elastic link design by Laura Harrison.

Laura has recently completed the Manufacturing Engineering Tripos at the IfM and next year will be studying Industrial Design Engineering at the Royal College of Art.

Third prize

Dr Jack Luo and Dr Yong Qing Fu

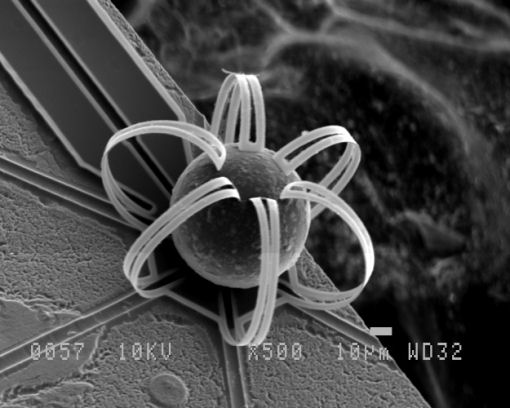

'Nanohand and its captured ball'

The photograph that has won third prize was taken by Dr. Jack Luo a senior research associate and Dr.Yong Qing Fu a research associate working for Professor Bill Milne, in the Electrical Engineering Division, they will receive the third prize of an Epson Stylus Photo R240 printer that has been generously donated by Epson.

Dr Jack Luo and Dr Yong Qing Fu have developed this microgripper using a polymer, metal and Diamond-Like Carbon (DLC) trilayer structure. The photo was taken using a scanning electron microscope and shows a ball only ~65µm across captured in the cage of the microgripper. This device is suitable for trapping and holding biological specimens such as cells without applying a force directly on it, thus avoiding potential damage to the cell. The compressively stressed DLC layer expands once the structure is released from the substrate, and forms a closed microcage. A pulsed current of <10mA with duration of milliseconds can be applied to generate a thermal stress on the polymer side, and force the microcage to open. The power to open the microcage is less than 10mW. The advantage of a pulsed operation is to keep the device temperature lower, thus they can be used for biological applications. This particular device has a diameter of ~110µm, but Jack and Yong Qing have made devices ranging from 30 to 200µm in diameter. The research was sponsored by The Cambridge-MIT Institute (CMI).

Jack Luo a senior research associate, is developing various microsystems for microelectronics, medical and biological applications, and acoustic wave based biosensors to detect cancers at molecule level.

Yong qing Fu is a research associate his research interests include MEMS, shape memory alloy, surface science and thin films. He has developed several types of TiNi thin film based microactuators for biomedical applications.

Other entries in the Department's 2006 photo competition can be seen at www.eng.cam.ac.uk/photocomp/2006/

© Copyright notice

You may copy an image from the photography competition, reproduce it, and distribute it, but only if you clearly attribute the image to the student or academic who took the photograph, state that they work in the Department of Engineering at the University of Cambridge, and acknowledge Epson's sponsorship of the competition. It would also be courteous to provide a links to www.eng.cam.ac.uk and www.epson.co.uk. We would be delighted to hear where the images have been used. Please contact marketing@eng.cam.ac.uk to let us know.