Dr Mohammed Elshafie, Cambridge Centre for Smart Infrastructure and Construction (CSIC) Co-Investigator, is collaborating with a team from The Alan Turing Institute, Imperial College London and 3D printing company MX3D to measure, monitor and analyse the performance of a 3D printed footbridge due to be installed across a canal in Amsterdam later this year.

The sensors collect data on structural measurements including strain, displacement and vibration and measure environmental factors such as air quality and temperature.

Dr Mohammed Elshafie

The 12 metre-long stainless steel bridge will be the world’s largest 3D printed metal structure. About a third of the bridge has already been printed in a lab in the Netherlands and the finished structure will cross the Oudezijds Achterburgwal canal in central Amsterdam and be open to pedestrians and cyclists.

An innovative sensor network will be designed and installed on the bridge by a team of structural engineers, mathematicians, computer scientists and statisticians. CSIC is part of the team working on the design and installation of the sensor network.

“The sensors collect data on structural measurements including strain, displacement and vibration and measure environmental factors such as air quality and temperature,” said Dr Elshafie. “This enables engineers to monitor the ‘health’ of the bridge in real time and observe and record how it changes throughout its lifespan. The sensor network provides a ‘nervous system’ for the bridge and creates a living laboratory for the researchers and engineers.”

The data from the sensors will be inputted into a digital twin of the bridge – a living computer model developed by the Steel Structures group at the Department of Civil and Environmental Engineering at Imperial. The digital twin will imitate the physical bridge with growing accuracy in real time as data from the sensors comes through. The performance and behaviour of the physical bridge can be tested against its digital twin, which will provide valuable insights into designs for future 3D printed metallic structures. It will also enable the current 3D bridge to be modified to suit any required changes in use, ensuring it is safe and secure for pedestrians.

Samples of the 3D printed structure are currently being tested by the Steel Structures team to anticipate the behaviour of the bridge under loading from pedestrian or cycling traffic, and inform its design.

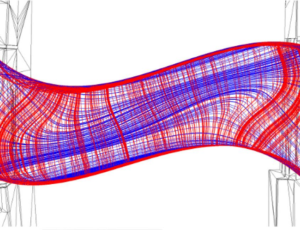

The bridge being printed. Image: Olivier de Gruijter

The bridge being printed. Image: Olivier de Gruijter

Professor Mark Girolami, Chair in Statistics in the Department of Mathematics at Imperial College London and lead of The Alan Turing Institute-Lloyd’s Register Foundation programme in data-centric engineering, said: “The 3D printed bridge being installed by the MX3D team later this year will be a world first in engineering. This data-centric, multidisciplinary approach to capturing the bridge’s data will also mark a step-change in the way bridges are designed, constructed, and managed, generating valuable insights for the next generation of bridges and other major public structures.

“It is a powerful embodiment of what data-centric engineering can deliver as a discipline, and I look forward to seeing the bridge in action later this year.”

This project is a collaboration of partners including software engineers Autodesk and The Amsterdam Institute for Advanced Metropolitan Solutions, who will explore new ways to use and connect the bridge data with other data streams in the city. The build of the bridge is supported by the Lloyd’s Register Foundation.

Data captured from the bridge will be made open for research, and MX3D launched an open call (closed February 2018) seeking creative and innovative ideas that will make use of the collected data.

This article was reproduced from the original article published on the Imperial College London website. Read the original article here.

Image credit MX3D