Researchers have identified the criteria needed to develop tough and damage-tolerant mechanical metamaterials. Using experiments and numerical analysis, the team investigated the continuum theories of elastic fracture mechanics in three-dimensional architected solids.

The design protocol we have developed will enable the selection of optimal structural metamaterials for applications ranging from battery electrodes to thermal insulation.

Dr Angkur Shaikeea

Mechanical metamaterials are an emerging class of ultralight materials with extreme functional properties, made possible thanks to recent advances in additive manufacturing. Its potential for use in a plethora of engineering applications, particularly as structural components, owing to its simultaneous high strength at low densities, for example, has been limited due to difficulties in evaluating failure and understanding 3D metamaterials’ tolerance to damage and defects.

But now, research, led by the University of Cambridge, takes a new look at the fundamental concepts of fracture mechanics in truss-based architected solids and provides a framework that has the potential to be applied to any 3D metamaterial, regardless of its topology and its constituent material properties. The aim here is to aid designers with a tool to not only invent new failure resilient 3D metamaterials, but also provide an engineering methodology to design with these materials. The results are reported in the journal Nature Materials, accompanied by a news and views report, also in Nature Materials.

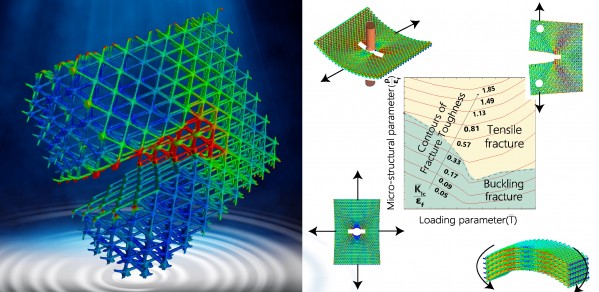

Using cutting-edge experimental techniques, the researchers were able to generate ‘fracture mechanism maps’ that can be used by metamaterial designers to evaluate failure in different applications and assess the toughness of the metamaterial – something that has, until now, been the limiting factor in mechanical design. These ‘maps’ enable the optimised metamaterial topology to be selected, based on the desired design parameters, for example, parent material property and lattice relative density.

Dr Angkur Shaikeea, the Ashby Research Fellow in the Department of Engineering and lead author of the study, said: “The design protocol we have developed can be used to identify topologies that maximise the damage tolerance and/or fracture toughness of metamaterials. This will enable the selection of optimal structural metamaterials for applications ranging from battery electrodes to thermal insulation.”

The research, supervised by Professor Vikram Deshpande in the Cambridge Centre for Micromechanics, included collaboration with Professor Xiaoyu (Rayne) Zheng’s group at the University of California, Los Angeles, U.S.A.

References:

Angkur Jyoti Dipanka Shaikeea et al. ‘The toughness of mechanical metamaterials’. Nature Materials (2022). DOI: 10.1038/s41563-021-01182-1

James Utama Surjadi and Yang Lu. ‘Design criteria for tough metamaterials’. Nature Materials 21.3 (2022): 272-274.