The winning image in the photo competition recently held at the Department of Engineering, was taken by Kathryn Jackson, a PhD student working for Dr Julian Allwood, at the Institute for Manufacturing.

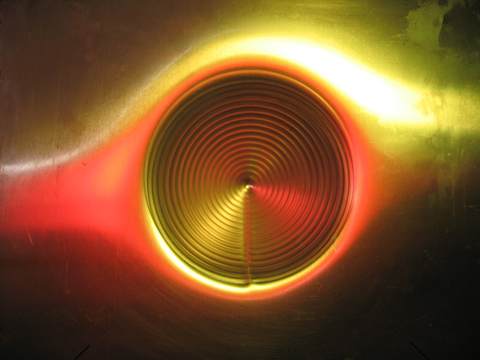

The photograph is a plan view of a cone shape formed by incremental sheet forming (ISF). The cone has a diameter of 150mm and depth of 75mm and was formed on a 360 x 360 mm sheet of aluminium. The shape was produced by a mobile indenter with a hemispherical tip which followed contours of the cone, incrementing vertically downwards by 4mm at the end of each revolution, which produced the seam that can be seen at the 6 o'clock position. Yellow and red light highlights the wavy surface that is characteristic of incremental sheet forming. The cone was produced as part of a qualitative study into the effect of vertical pitch on the surface waviness.

The process can be used to form more complicated asymmetrical geometries with a smoother surface finish by reducing the vertical pitch between contours: a pitch of 0.2mm gives a surface which has no visible 'waviness'. The process is an attractive alternative to pressing for small production sizes because no specialised tooling is required. In addition, the mechanics of the deformation is such that failure is suppressed and much higher strains can be achieved in ISF than conventional metal forming processes. There are also ecological benefits: the project requires less energy and materials in comparison to pressing because of smaller tool forces and no need for specialised tooling. The process is therefore being developed as a sustainable manufacturing technology and has generated significant industrial interest since the project started in October 2004.

The project is based on a machine commissioned in October 2004 at the Institute for Manufacturing (Manufacturing and Management Division). The aim of Kathryn's research is to improve the process capabilities by developing effective ways to control the deformation and improve geometric accuracy, as well as building an understanding of the mechanics of the deformation. Kathryn's projects will include measurement and prediction of tool forces in ISF, development of real-time process control using force and position feedback to improve geometric accuracy and experimentation with modifications to the process set-up to localise the deformation.