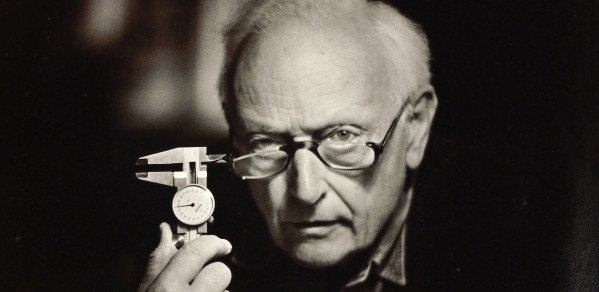

Alumnus Alex Moulton was a remarkable man and a brilliant engineer. His professional life was devoted to the research, development, design and manufacture of advanced and innovative products most notably the revolutionary small-wheeled lightweight Moulton Bicycle, models of which are still in production, more than 50 years after the initial development work.

Alex Moulton was a remarkable man and a brilliant engineer. His professional life was devoted to the research, development, design and manufacture of advanced and innovative products … the Moulton bicycle is the greatest work of 20th century British design

The Right Honourable Lord (Norman) Foster of Thames Bank

April 9th, 2020 marked one hundred years since the birth of Dr Alex Moulton, regarded by many as one of the most significant design engineers of the twentieth century. Moulton was a mechanical engineer and a specialist in the design of suspension systems. He was responsible for the smooth ride associated with a large range of cars built by the British Motor Corporation (later British Leyland), starting with the ever-popular Mini, first released in 1959.

Dan Farrell looks back over the life of Dr Alex Moulton CBE, documenting his many innovations and his lasting legacy to engineering.

Few 20th century engineers have made such a contribution to the modern world – particularly in the transportation field – as Alex Moulton. However, if asked to name Alex Moulton’s greatest innovation, one could describe the answer as ‘too close to call’. On one side we have his eponymous small-wheeled, full-suspension bicycle – still in manufacture and a great export success fifty years after its launch – attracting tributes from the likes of Lord Foster and Sir James Dyson as well as discerning cyclists worldwide. On the other, one could cite the Moulton rubber- and gas-sprung suspension units – cone, and the interconnected Hydrolastic and Hydragas systems – which were to be found under all four corners of over twelve million British cars from the 1959 Mini to the 2003 MGF. One could also argue for the Moulton double-bogie coach that offered unparalleled ride comfort and safety but, despite several joint-ventures, never saw series production.

There is less doubt over the period of his life when his work was most prolific. During the closing months of 1962, with the rubber cone spring firmly established and well-proven on the Mini, Moulton’s fluid-interconnected ‘Hydrolastic’ suspension was introduced on the new Morris 1100 to universal acclaim. Scarcely six weeks later, the Moulton bicycle received an overwhelming response when launched at the Earl’s Court Cycle Show. Moulton’s Marketing Manager, David Duffield, later commented that “we had to beat them off with sticks – at the show we were desperately short of manpower and we had to enlist friends, relations and anybody else to help us”. Alex Moulton became a public figure overnight as journalists from all fields penned articles about the ground-breaking Moulton products and interviews with the man himself appeared in newspapers, magazines and on the television. On December 9th, racing cyclist John Woodburn broke the Cardiff-London speed record, at a stroke establishing the reputation of the new bicycle. At the time, Moulton Developments was a small organisation based in the stable block and carriage works in the grounds of Alex Moulton’s Jacobean mansion, The Hall. Thanks to the success of the Moulton bicycle and Hydrolastic suspension, the scale of business was to change dramatically by the end of the year.

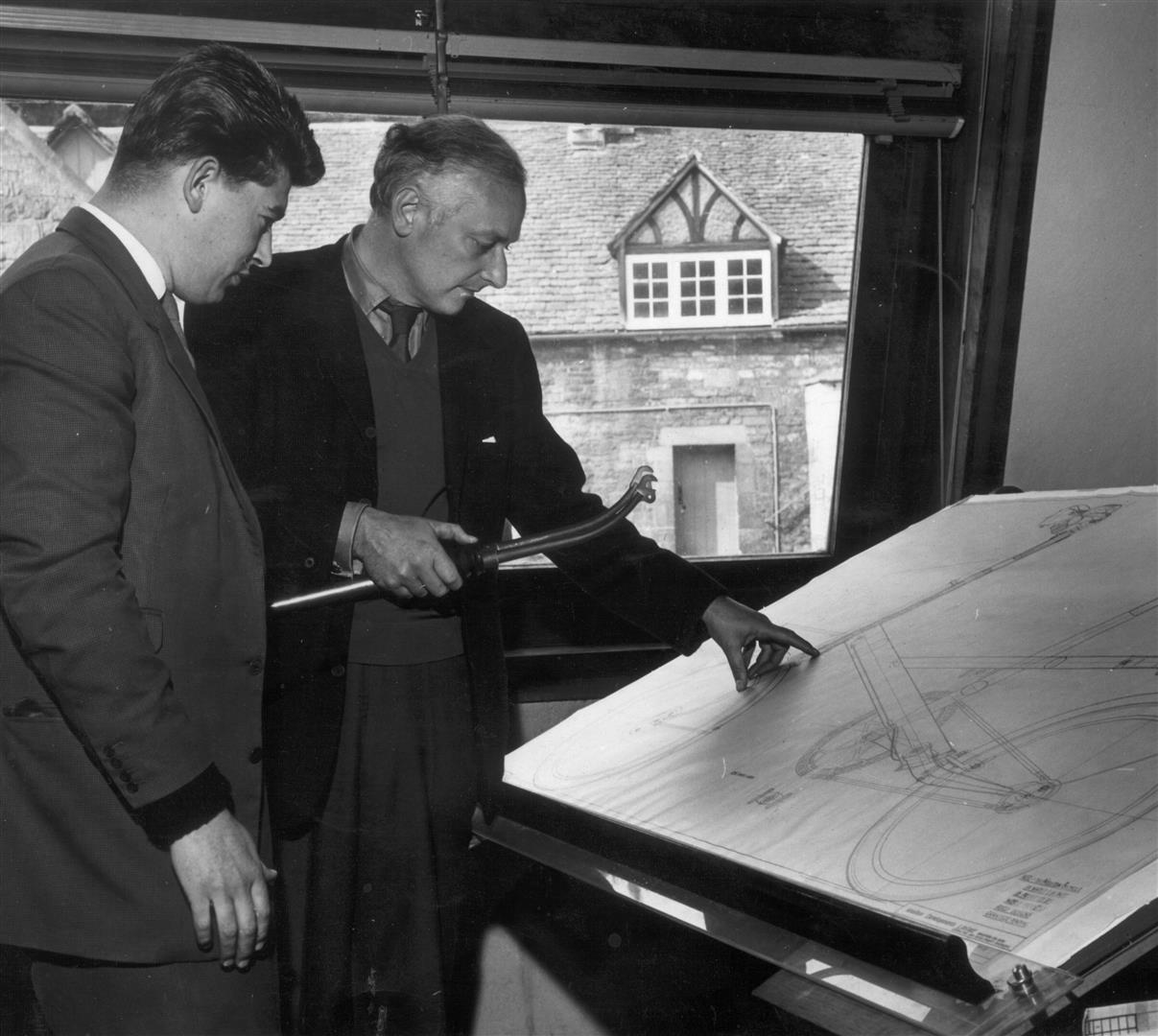

Alex Moulton (right) discussing the finer points of the front suspension of the Moulton bicycle with draughtsman Brian Cottrell (1962).

Moulton was born in Stratford-upon-Avon in 1920, youngest child of John and Beryl Moulton; great-grandson of Stephen Moulton. Stephen was a friend of Charles Goodyear, and following Goodyear’s discovery of the rubber vulcanisation process, he returned to England with this knowledge and established a rubber works – Stephen Moulton & Co. - in Bradford on Avon, Wiltshire. Having formed a strategic alliance with George Spencer & Co. (eventually merging into George Spencer, Moulton & Co – ‘Spencer Moulton’ in 1891), Moulton became famous for the supply of rubber springs for railway buffers and draw-bars as well as carriage interconnects, hoses etc. to rail companies world-wide.

Alex Moulton’s education was interrupted by World War Two. A Mechanical Sciences undergraduate at King’s College Cambridge when war broke out, he started work as an assistant tester at Bristol Aeroplane in Patchway whilst waiting to be called up. His talents in engineering were soon noticed, and he was promoted to Junior Technical Assistant in June 1940. Following a devastating air-raid in the September, Alex was thrust into the position of Roy Fedden’s assistant on the Centaurus engine – Adrian Squires having been killed by enemy action. In a reserved occupation, he felt some guilt at not fighting the war in the skies over Britain, but he knew that those brave pilots looked to the engineers at Bristol for continuous improvement in their aeroplanes.

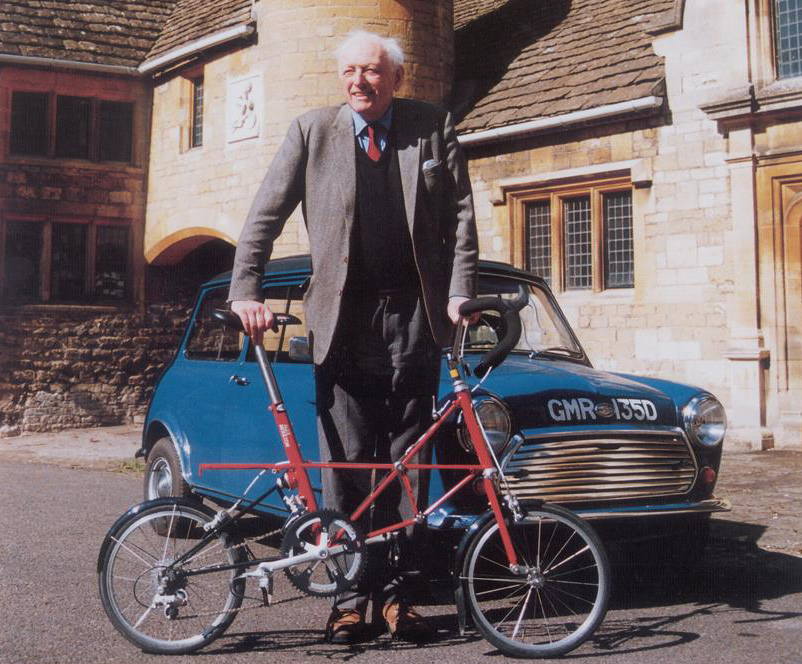

The Moulton 'stowaway' was one of the first bicycles designed to be transported by car. Long before the modern era of folding bicycles, these comparatively rare models separated into two parts to fit easily into the boot of even a small car. Here Alex Moulton is preparing to load his bicycle into his Morris 1100 - the first car with Moulton Hydrolastic suspension. Photo: courtesy Moulton Bicycle Company

In 1945, Alex returned to Bradford on Avon, having accepted a position within the family firm. Even at this early stage, he had discovered the design potential offered by methods of permanently bonding rubber to metal and was keen to develop shear and torsion springs using this new process. As the technical staff of Spencer Moulton returned to London (having relocated to Bradford during hostilities), Alex began his experiments. Before long, frustrated by his incomplete engineering knowledge and with the blessing of his bosses, he went back to Cambridge to finish his degree. As is so often seen nowadays, his experience at Bristol increased his desire to learn and his ability to put theory into practice.

Perhaps influenced by the unforgiving nature of aeronautical engineering, Moulton’s thread of needing to achieve a deep understanding of fundamentals before tackling a problem was to run throughout his career. Whilst the properties of rubber in compression and the simple springs constructed in this way were well understood, loading cases such as shear and bending were relatively untested. Moulton was intrigued by the ‘Torsilastic’ tubular rubber bush pioneered by Alvin Krotz and, using this as proof of concept, developed his own – somewhat simpler to attach to a chassis – version, later known as ‘Flexitor’ suspension and in widespread use on road trailers, the Bond Minicar and the Austin Gypsy,

Alex Moulton (left) and Alexander Arnold 'Alec' Issigonis (1906-88, knighted 1969) in 1962 at the launch of the Morris 1100, first car to feature Moulton Development's Hydrolastic suspension — developed by Moulton in association with Issigonis, British Motor Corporation's chief designer. Photo credit: British Motor Industry Heritage Trust Film & Picture Library

At this stage, striving to establish some laws of behaviour for these new rubber springs, Moulton recruited Philip Turner from Cambridge University. Turner, a brilliant physicist, made mathematical sense of the fatigue and creep tests that Spencer Moulton were undertaking and made a great contribution to the reliability and durability of rubber suspension systems that, in later years, would appear on millions of British cars. Moulton and Turner published a paper in 1950 – ‘Influence of Design on Rubber Springs’ and this was followed a year later by ‘Development and Testing of a Series of Rubber Suspension Units’. Despite Spencer Moulton’s strong links with the rail industry, Moulton was keen to exploit his inventions in the rapidly expanding automotive sector. By good fortune, he had recently formed a strong friendship with a project engineer at Morris Motors by the name of Alec Issigonis.

Issigonis, a suspension expert himself, had shot to fame in 1948 with the instant success of the Morris Minor. He was, however, disparaging of Moulton’s work. “Rubber”, he stated, “is not an engineering material”. It was not until 1953, after Issigonis had left Morris to join Alvis, that Moulton was able to equip a Minor with rubber suspension. Tested at MIRA, with a modified seismograph on the rear seat to measure vertical acceleration, this car was the first ever to cover 1,000 miles on the pave without fault. Issigonis was suitably impressed and brought Moulton into his team at Alvis. Rubber cone springs – developed initially as engine mounts – working in compression and shear were used in series ‘nose-to-nose’ on struts for the vehicle suspension. The ride was satisfactory but Moulton and Issigonis, having toyed with the idea of hydraulic interconnection for years, realised that if the springs were placed ‘back-to-back’ they could be used as fluid-displacers as well as primary springs. Moulton was later to recall “the revelation at Coventry, with Alec driving, of experiencing the ‘big car’ ride due to the lowered pitch frequency. The reality of the benefit of fluid interconnection was thus revealed and the seed was sown, not that we realised it then, for a radical new suspension to be made in vast numbers”.

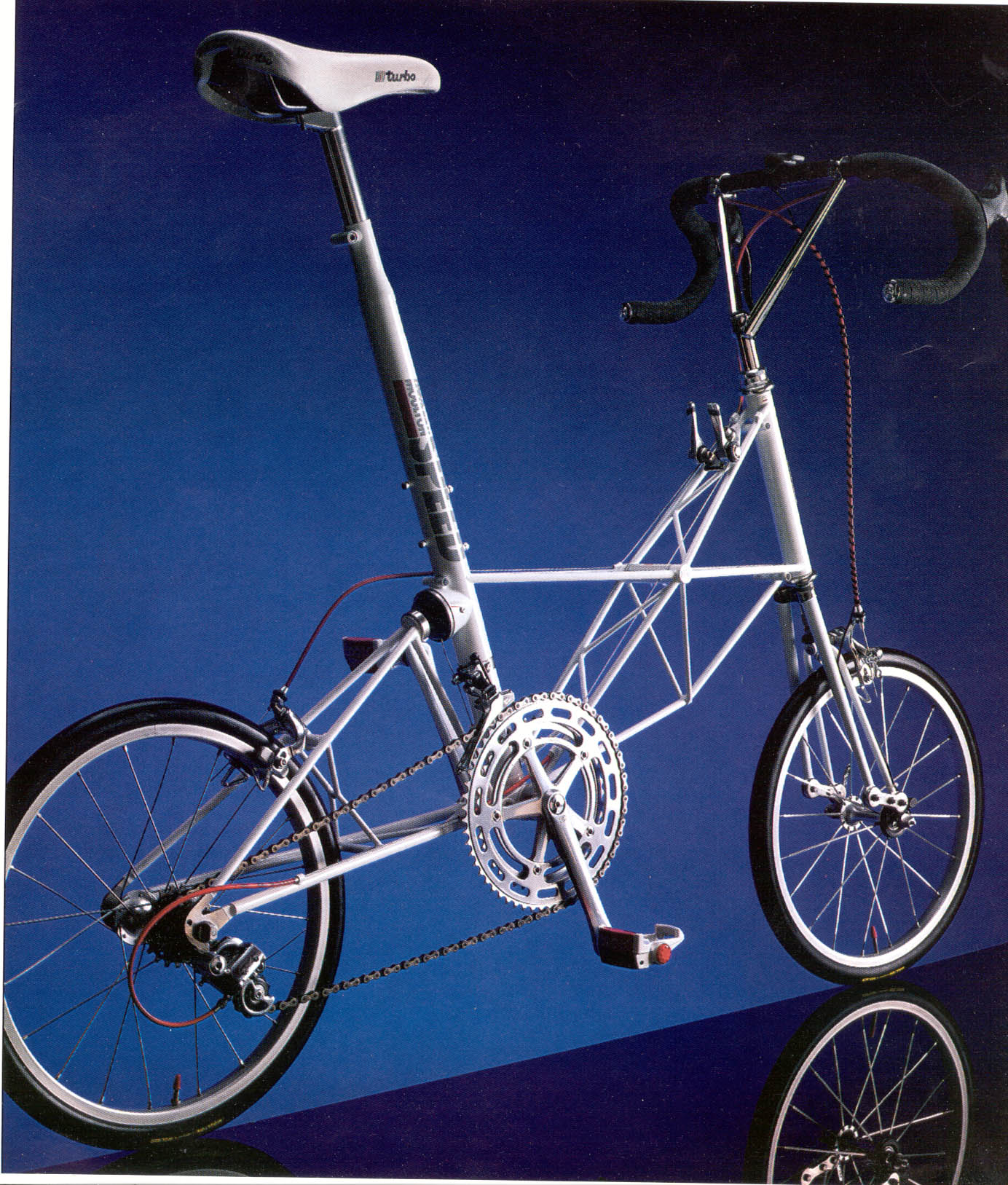

The Moulton AM SPEED bicycle was designed for the Race Across America, the world's toughest bicycle race. American Dave Bogdan rode the first AM SPEED from coast to coast in 1988 - 3,117 miles - and finished 8th out of 35 starters in 10 days 15 hours.

1955 saw a great deal of change. Spencer Moulton was absorbed in the Avon Rubber Company. Issigonis moved back to BMC and persuaded them to sign up Moulton as a suspension consultant on an exclusive basis. Moulton himself, completely convinced by the benefits of interconnection, turned the stable block at his family home into a development and testing workshop and worked night and day to analyse the characteristics, obtain quantifiable data and derive formulae to predict behaviour of the new suspension systems. Looking at his sketches from this creative period, there are many fascinating concepts that defied any analysis other than the reality of making and testing – very much the Moulton design ethos – and his team in the workshop were not short of work. Moulton would later comment that “we had no analogy to fall back on; indeed the devices were more akin to biological organs than engineering mechanisms”. As the Hydrolastic concept reached the convergence stage – a levered, short-stroke unit with a reinforced diaphragm pushing the hydraulic fluid through a damping valve, with a rubber ‘cheese’ in shear and compression as a bounce spring – stroking rigs tested each design iteration for fatigue problems. Moulton used this ‘design – make – test’ feedback loop to great effect. A ‘cheese board’ showing the failure modes of all these prototypes still exists, and the eventual results are ably demonstrated by a Hydrolastic unit removed from a car after 250,000 miles and found to be within original equipment specifications for springing and damping.

Moulton’s company – Moulton Developments – was set up as a triumvirate between BMC (as car manufacturers), Dunlop (who would manufacture the suspension units) and Moulton himself. Despite its remote location from the industrial heartlands of Longbridge and Coventry, Moulton Developments was to stay in the grounds of The Hall in Bradford on Avon. With the first Suez Crisis focusing minds on fuel economy, Issigonis was charged with the urgent task of “driving these bubble cars off the roads” by Leonard Lord at BMC. The now-legendary Mini was launched in 1959, suspended on Moulton rubber cone springs similar those first used at Alvis. Given the limited development time available, it had not been possible to progress the Hydrolastic interconnected suspension to production in time for the Mini launch. Hydrolastic was to debut on the Morris 1100 in 1962, and eventually found its way onto the Mini in 1964.

Alex Moulton in the 1980s with his Jaguar XJS, Rolls-Royce Silver Shadow, Austin Metro and Citroen GSA. The latter two seem out of place, but the Metro is the one he converted to interconnected Moulton Hydragas suspension to persuade Austin-Rover that they should fit the proper system; whilst the Citroen he deeply admired on many levels and considered it to be the French company's finest design. Photo: courtesy Moulton Bicycle Company

Whilst eking out petrol rations in 1957, Moulton bought himself a ‘Curly’ Hetchins bicycle as, in his words, “a serious alternative means of locomotion”. Immediately he was both delighted and intrigued by the efficiency and liveliness of this lightweight steed, but he was also struck by the inconvenience of (and danger posed by) the horizontal top tube and the lack of facility for carrying luggage. Inspired by the space liberated by the reduction of wheel size on the Mini, validated by comprehensive testing, Moulton conceived the idea of a small-wheeled bicycle – with an open frame for convenience, front and rear suspension to improve rider comfort and allow the use of high-pressure tyres, and large luggage carriers. Following some analysis of riding positions and efficiencies, he approached Dunlop for help in the design, testing and manufacture of suitable tyres and rims; those currently available being for juvenile bicycles and in no way performance orientated. Dunlop, at that time employing over 1,000 staff in the manufacture of Moulton rubber springs and flexible couplings for BMC, acquiesced to put their technical weight behind the bicycle project. With the fundamentals in place, he embarked on another challenge, one that he had not faced in aeronautical or automotive fields – the search for form.

Whilst clearly having difficulty in resolving the appearance of his new bicycle, Moulton was sensitive to public reaction and sought to avoid shocking potential buyers. Given that bicycle design had stood still for seventy years, one can appreciate why he took so much care over seemingly minor details. For example, the alignment of the chain was constrained by the requirement to keep the ‘top run’ parallel to the main tube, and the ‘lower run’ parallel to the ground; and the unnerving ‘tallness’ of the head and seat tubes was disguised by ‘billiard cue’ paintwork. Having progressed from models to prototypes, he eventually approached Raleigh with a view to offering them a licence to manufacture. Hugely dominant in the industry, Raleigh were initially keen but soon dithered. Moulton, with characteristic conviction, built a bicycle factory in the grounds of The Hall and launched the Moulton bicycle in November 1962.

Alex Moulton in 2010, with the Golden Jubilee space frame Moulton Bicycle and a Mini. The Mini and Moulton-designed bicycles used an innovative series of suspension systems designed by Moulton with Moulton Developments. Photo: courtesy Dan Farrell, Moulton Bicycle Company

Not only were the appearance and configuration of this new bicycle novel, the pressed-and-welded construction methods were clearly more influenced by automotive practice than the lugged-and-brazed bicycle frames that were ubiquitous at the time. Thanks to the ferocious demand for the Moulton bicycle, Alex’s friends at BMC stepped in and offered to build it for him. Within a year, Moulton stood as the second-largest frame builder in the country and Raleigh was forced to take notice of, and respond to, their upstart rival. The Raleigh RSW16, with fat tyres and no suspension to circumvent Moulton’s patents, seriously damaged the reputation of the small-wheeled bicycle, despite competition successes by Moulton’s track team.

In the years after 1962, Moulton Developments grew rapidly, both as bicycle manufacturers and as design authority and technical masters of the automotive suspensions. In the former case, the factory in the grounds of The Hall was to manufacture most of the export bicycles – up to 250 a week – before Raleigh acquired Moulton Bicycles Limited in 1967. The suspensions business, with thousands of Hydrolastic units being fitted on Minis, 1100s, 1800s, Austin 3 litres and Maxis, was to progress from the iterative design-make-test methodology to a much more scientific process, beginning with a four-post shaker table allowing ride measurements to be taken in the laboratory and eventually leading to predictive mathematical (computer) modelling. Key to these innovations was Anthony Best, who joined Moulton Developments in 1967 and was to lead the evolution from Hydrolastic to Hydragas suspension, with a nitrogen gas spring replacing the rubber to give a less harsh ride in ‘full bounce’ mode.

Hydragas was introduced on the Austin Allegro in 1973, followed by the Princess in 1975 and the Metro in 1980. In the case of the Metro, Moulton was dismayed to find that Spen King refused to interconnect the units front-to-rear in the intended manner, preferring to use telescopic dampers and a small side-to-side interconnection pipe. With typical candour, he bought an example from Leyland, installed a ‘proper’ interconnected Hydragas system, brought the top brass down from Longbridge and got them to drive it. Needless to say, the Rover Metro’s suspension was interconnected. Hydragas enjoyed a late flowering on the MGF sports car, with the last new car fitted with Moulton suspension rolling off the line in 2002 – 43 years and 12 million cars after the first.

Following the sale of Moulton Bicycles to Raleigh, Alex Moulton was retained as a consultant. Unimpressed by the constraints of such a large organisation, Moulton took the opportunity to use the technology developed in his suspensions business to undertake a fully quantified scientific study of the bicycle, thought to be the first of its kind. After Raleigh ceased manufacture of Moulton bicycles in 1974, Alex, again determined to ‘go it alone’, was keen to retain complete control of his new bicycle company, Alex Moulton Limited. With his eyes firmly fixed on excellence in design and engineering, the new ‘AM’ series bicycle was to be labelled by some as “a bicycle for doctors, engineers and perfectionists”.

Successive evolutions of this multi-tube space-frame bicycle were to find friends all around the world, from all walks of life, and all attracted by the seemingly magical ride offered by Moulton’s steel and rubber design. Still manufactured in the original workshops in Bradford on Avon, the Moulton bicycle remains in high demand, particularly in export markets. Following a re-organisation in 2008, its future – both in design and manufacture - is assured.

Moulton was an idiosyncratic, intensely intelligent and strongly driven individual. He held great faith in his convictions and possessed the courage to follow them to fruition. Like those he worked with in his younger days – Sir Roy Fedden, Sir Alec Issigonis – he could be a difficult man to disagree with, as many found to their cost. He did, however, maintain a select group of valued colleagues who knew his foibles and remained immensely loyal, several spending their entire working lives with Moulton. At times he would indulge his staff – cricket nets on the lawn, kayaks on the river – but he was not a man to suffer fools.

Moulton’s engineering legacy, aside from the artefacts themselves, lies in his methodology of understanding first principles followed by the relentless design-make-test feedback loop, interpolating the test results wherever possible. There seemed to be no limit to the number of design iterations he would take, he would simply continue until he was satisfied with the result. In addition, he was sensitive to the emotional responses felt by users of his designs and was very taken by the Japanese idea of the ‘spirit’ of an artefact, inherited from its creator.

The style embodied in both his life and his work – and there was seldom a boundary between them – was, in scale and substance, evocative of the great engineers of the Industrial Revolution. Having seen it all through his own eyes, he lamented the demise of British manufacturing - the relentless off-shoring of jobs and the shameless pursuit of money. He believed in homo faber (“Man the Maker”) and the satisfaction and moral rewards thus gained:-“Man should make things – make a profit, of course, but don’t take the money gain as the prime judgement”.

About the author

Dan Farrell BSc(Hons) MTech CTPD CEng FIED, is group technical director at the Moulton Bicycle Company. He is an accomplished cyclist, and is known for his technical and travel writing. He has been involved with Moulton bicycles for twenty-six years and was elected a Fellow of the IED in 2011.

The Alex Moulton Charitable Trust

The Alex Moulton Charitable Trust is responsible for The Hall estate in Bradford on Avon, home of the late Dr Alex Moulton. The work of the charity includes conservation of the magnificent Jacobean house, grounds and extensive collection, and the education of visitors of all ages in the subjects of engineering, design, architecture and local industrial history through a range of events including guided tours and talks. To find out more about the Trust and upcoming events at The Hall, please visit the website at moultontrust.org