The Department of Engineering is one of a select group of UK academic institutions to win funding for ground-breaking projects that will tackle the challenges facing manufacturing in the 21st Century.

A total of £21 million has been raised from government grants and industrial sponsorship for four 'Grand Challenge' areas.

The manufacturing Grand Challenges have been set up by the Government to encourage the UK's Innovative Manufacturing Research Centres (IMRCs) to address issues that have the potential for significant impact on national manufacturing priorities. The IMRCs are academic institutions recognized by the Government as being at the forefront of manufacturing understanding and research.

Of the five Grand Challenges to be funded the Department is involved in four:

Innovation and productivity

This Challenge aims to improve the way UK industry harnesses the outputs of research to produce high value products and services. The UK has a strong research capability in science, technology and engineering and a vibrant economy supporting industrial growth. However, to compete successfully in 21st century global markets, the research and industrial communities need to develop new ways of working together in order to achieve faster and more effective exploitation of research. Successful commercialisation of new ideas is seen as a key way to close the current productivity gap between the UK and other industrialised countries such as the US, France and Germany.

This Grand Challenge, which has been awarded £3.5 million of funding, is a joint venture between The Institute for Manufacturing (IfM), part of the Department of Engineering, and researchers at Cranfield, Imperial College, Liverpool and Loughborough universities.

For further information please contact David Probert.

Life-time information requirements

Many engineering companies are undergoing a shift from product delivery to through-life service support. Firms are increasingly required to supply products and to provide support services throughout the product lifetime. This requires new business, operational and information system models that extend thirty years or more into the future. The overall aim of this research project is the identification of approaches to information and knowledge management that may be applied to the through-life support of long-lived, complex engineered products. The lifetime may be 10, 20 or 30 years and beyond, during which time the 'information and knowledge' will be stored, accessed, used and recreated many times over and in many different situations and contexts.

This Grand Challenge, which has been awarded just under £3.5 million of funding, the project team includes partners from Bath, Cambridge, Heriot-Watt, Lancaster, Leeds, Liverpool, Loughborough, Reading, Salford and Strathclyde universities as well as the Advanced Institute of Management initiative.

For further information please contact Professor John Clarkson.

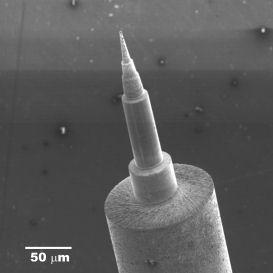

Micro-manufacturing

A radical new approach to the manufacture of miniature 3D objects will be the focus of this Grand Challenge, enabling UK business to be at the forefront of developing the next generation of electronic products in a wide range of sectors. The project, dubbed '3-D Mintegration', will establish new techniques to enable the production of genuine 3D, multi-material products in the automotive, aerospace, telecommunications, medical and consumer sectors.

Current micro-engineering techniques only permit the manufacture of products using single materials that typically have to be built up in multi-layer configurations. This £9 million, 4-year programme sets out to create a shift in manufacturing by developing the technologies and strategic approaches required to produce complex 3D miniaturized devices and assemblies.

The Institute for Manufacturing (IfM), part of the Department of Engineering, are collaborating with Cranfield, Greenwich, Heriot Watt, Loughborough and Nottingham universities as well as the National Physical laboratory. Twenty-three companies are also supporting the project.

For further information please contact Dr Bill O'Neill.

Regenerative medicine - a new industry

This Grand Challenge will focus on an emerging new healthcare industry that offers enormous potential to contribute to the UK economy. Regenerative medicine is an exciting branch of medicine in which cell and tissue based therapies can be used to alleviate and cure a wide range of conditions. It includes the fields of transplant surgery, tissue engineering, biomaterials and stem cell applications. Scientific research has already revealed the potential power of such activities. This project will focus on transforming established biology into commercial, affordable therapies.

The project has funding of over £5 million, is led by Loughborough University and includes collaborators from Nottingham, Liverpool and Ulster universities.

- Innovation and productivity

- Life-time information requirements

- Micro-manufacturing

- Regenerative medicine - a new industry