On his industrial experience summer placement, a Department of Engineering student experienced the real-world applications of a 3D printer in a bustling rail manufacturing centre.

The range of transferable skills offered by the 3D printer has been enormous.

Aiden Chan

During the summer break, Aiden Chan, a second-year engineering student, had the chance to work at Progress Rail Services – one of the largest suppliers of railroad and transit products including switches, crossings, buffer stops and transition rails – at its Sandiacre site.

Aiden was assigned to help integrate a 3D printer into the company’s operations. He participated in the device’s testing and calibration and ensured the printer was capable of producing templates that met Progress Rail’s demanding specifications.

After familiarising himself with the printer’s machine code, optimising the setup process and customising the printer’s web interface in HTML, Aiden wrote up a comprehensive user guide to assist future employees and others unfamiliar with the system. He also looked into how the printer’s applications could be expanded through the company.

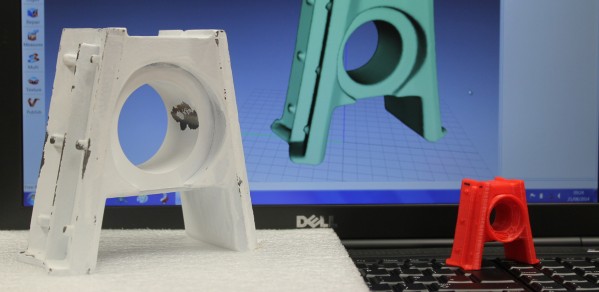

One immediate use for the 3D printer was to create scale models of products to be shown to clients and employees alike. To construct these, several separate pieces were printed and later assembled.

In addition to the printer, a 3D scanner was introduced at Progress Rail to facilitate on-site rail inspections. Aiden likewise learned this system and also produced a user guide that documented the entire process from scanning an object to 3D printing a scale model.

“I have learned a lot in my time at Progress Rail,” Aiden says. “My confidence in [computer-assisted drawing] has seen a large boost, and the range of transferable skills offered by the 3D printer has been enormous.”

Aiden is no stranger to working with 3D models – in his spare time, he constructs intricate LEGO sculptures in the form of dinosaurs, swordfish and robots.