The first Rex Moir Outstanding PhD Thesis Prizes have been awarded

The first Rex Moir Outstanding PhD Thesis Prizes have been awarded to former students at the Department of Engineering. Their research areas included using neural activity to control prosthetic limbs, harnessing diffraction in optical and photonic computing devices, and hybrid ventilation flows in buildings.

The Rex Moir prize is an opportunity for us to recognise the most outstanding thesis every year, and it is wonderful to see the breadth of topics that have won the top prizes and the awards.

Professor Colm Durkan

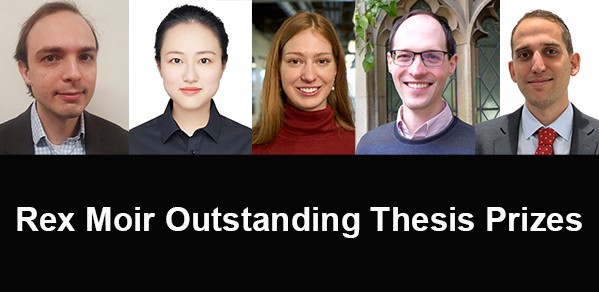

The two top prizes were given to Charles Micou and Minjia Chen, with Teja Potocnik, Matthew Waterson and Ben Wetherfield, also receiving Rex Moir awards for 2024 and 2025.

The awards are in remembrance of engineer Rex Moir, who matriculated in 1911. He became an officer in the Royal Engineers during the First World War and died in 1915, at the age of 22.

Head of Department Professor Colm Durkan said: “The Rex Moir prize is an opportunity for us to recognise the most outstanding thesis every year, and it is wonderful to see the breadth of topics that have won the top prizes and the awards.

"Well done to these students for these richly-deserved accolades of their work.”

Charles Micou

His 2025 thesis, Neural Sympathy: Towards Interfaces Compatible with Neural Plasticity, deals with design challenges for brain-machine interfaces arising from their changeable operating environment. Charles explained that these devices could translate neural activity directly into actions on a computer or with a prosthetic limb. They often assumed a fixed relationship between neural activity in the brain and intentions, on the assumption that the brain is a static environment.

“The representation of intentions and information within the brain is constantly changing as we learn new things. My thesis describes the design of a novel closed-loop optical interface in a highly plastic brain region responsible for spatial navigation, as well as more theoretical work on adaptive neural decoding.”

Charles studied for his MEng in the Department between 2012-2016, before returning as student in 2021 to start his PhD, under Professor Timothy O’Leary in the Information Engineering Division. He has also taught in Cambridge for ten years, is a researcher and affiliated lecturer in the Department, and a member of Magdalene College. His research aims to translate some of the computational/theoretical work in his thesis into concrete predictions about how humans change their behaviour in familiar situations.

He said: “This has the potential to tell us a surprising amount about how the human brain works without needing invasive surgery.”

Minjia Chen

The top 2024 award went to Minjia for her doctoral research on “Integrated photonic iterative processors for computing”. This focused on the conception and the experimental demonstration of the first integrated photonic iterative processor (PIP). This a novel architecture designed for fast and energy-efficient matrix inversions and matrix-inversion-intensive applications. By enabling direct reuse of input data in the optical domain, the PIP unlocks the potential to overcome the input/output (I/O) bottleneck that plagues conventional computing systems.

Her research has been published in Photonics Research and Nature Communications.

Minjia, of St Catharine’s College, received her bachelor's degree in Electronic Information Engineering from the University of Chinese Academy of Sciences in 2020. She studied for her PhD in the Electrical Engineering Division at Cambridge and is now a Senior Engineer at Shanghai Huawei Technologies Co. Her work is to develop algorithms and toolchains to enhance the speed and energy efficiency of hardware accelerators.

Teja Potocnik

Award-winner Teja Potocnik, completed her PhD in Engineering under the supervision of Dr Jack Alexander-Webber in the Electrical Engineering Division in 2024 and was a member of Lucy Cavendish College. Teja’s thesis, "High-throughput characterisation and device integration of nanomaterials", presents a fully automated methodology for characterising materials from microscopic images. This uses techniques such as computer vision and auto-routing to greatly accelerate material analysis and device design.

She aims for this work to enable a rapid shift from individual prototype devices to high-performance integrated systems, supporting the evolution from single-unit nanomaterial photodetectors, transistors, and LEDs to full image sensors, integrated circuits, and displays. By making advanced semiconductor research faster and more efficient, her high-throughput approach helps streamline the path from groundbreaking discovery to practical application.

Her latest paper is High-Throughput Ellipsometric Contrast Microscopy of Lateral 2D Heterostructures for Optoelectronics.

Matthew Waterson

Matthew Waterson completed his undergraduate degree in Civil, Structural and Environmental Engineering at Cambridge in 2017 and then joined Breathing Buildings, a pioneering hybrid ventilation company, as a graduate engineer. He returned to academia in 2020, studying for a PhD under Professor Gary Hunt in the Energy, Fluids and Turbomachinery Division and was a member of Churchill College.

In 2025 thesis “Hybrid Ventilation Flows”, Matthew explored the simultaneous combination of natural and mechanical ventilation on a fundamental level through the development of simplified mathematical models, supported by his laboratory experiments. He also won a 2025 CIBSE Dufton Silver Medal for fundamental research in building services engineering.

He now works as an engineer for Cambridge-based, Joel Gustafsson Consulting. which has a particular focus on providing robust engineering solutions to enable the energy transition.

Ben Wetherfield

Ben’s 2024 PhD “Diffraction-based optical architectures for processing one-dimensional data” was supported by the Richard Norman Scholarship. This was offered through the Engineering Department with further funding provided by The Cambridge Trust. Ben’s thesis research, in the Electrical Engineering Division's Centre of Molecular Materials for Photonics and Electronics evaluated opportunities and limitations of harnessing diffraction in optical and photonic computing devices. The work aimed to address questions relating both to on-chip photonic and free-space optical architectures, using a wide range of technical methodologies, including experimental optics, large-scale simulation, and mathematical asymptotic analysis.

During his time in Cambridge, he performed further research in computer-generated holography for display applications and developed technology with computer vision spin-out Prospectral. Ben, who was a member of Churchill College, also worked on the SpaceX Starlink satellite network as a software engineer in Los Angeles. He now works in New York City as a scientific and engineering consultant at Exponent, Inc.