Research Fellow Dr Babak Bakhit has encountered one of his most challenging projects to date – contributing to the European Space Agency’s (ESA) JUpiter ICy moons Explorer (JUICE) mission.

The JUICE mission was the most challenging, but at the same time, the most important and exciting project that I have been involved in. It was a great opportunity to contribute to such a large space-related project and I am keen on any life discovery on Jupiter.

Dr Babak Bakhit

The spacecraft is currently on its way to orbit Jupiter and investigate the planet’s three ocean-bearing icy moons – Ganymede, Callisto and Europa – with a suite of remote sensing, geophysical and in situ instruments. It is due to reach Jupiter in July 2031, with flybys en route to Venus (August 2025), Earth (September 2026), and Earth again (January 2029).

These moons are expected to have extraterrestrial liquid water under their frozen surfaces, which is the subject of significant interest as a key prerequisite for extraterrestrial life. The spacecraft will also explore Jupiter’s complex environment and its system (atmosphere, ring system, and magnetic environment) as a model for other gas giants in our solar system – these being Saturn, Uranus, and Neptune.

Dr Bakhit, who is from the Department of Engineering’s Electronic Devices and Materials Group, was responsible for applying a protective coating to state-of-the-art sensors that make up the radio and plasma wave instrument (RPWI). The RPWI consists of four 10cm diameter Langmuir probes for exploring the atmosphere around Jupiter’s icy moons.

Each probe is mounted at the end of three-metre-long deployable booms, enabling it to extend from the spacecraft body.

These probes, which will characterise plasma and measure radio emissions, are made of titanium grade 5 alloy and have spherical shapes, designed to be like eggshells, with a 400-micro-metre thickness. Resistor-capacitor circuit elements exist inside the spheres.

“To make the Langmuir probes sensitive enough to detect a wide range of frequencies and electrical charges (both electrons and ions), it was essential to coat them with special layers,” said Dr Bakhit. “In fact, the coatings needed to be extremely sensitive to the electrical charges and capable of surviving harsh environments, such as extreme weather, temperature, and radiation, during this mission.”

He added: “The coatings had to have excellent electrical performance, high temperature durability, chemical inertness, optical properties, and adhesion, together with high sensitivity to plasma density variations, and ultra-low surface roughness and sensitivity to contaminations. This combination of properties required the coatings to be made of a particular material with precise composition and nanostructure.”

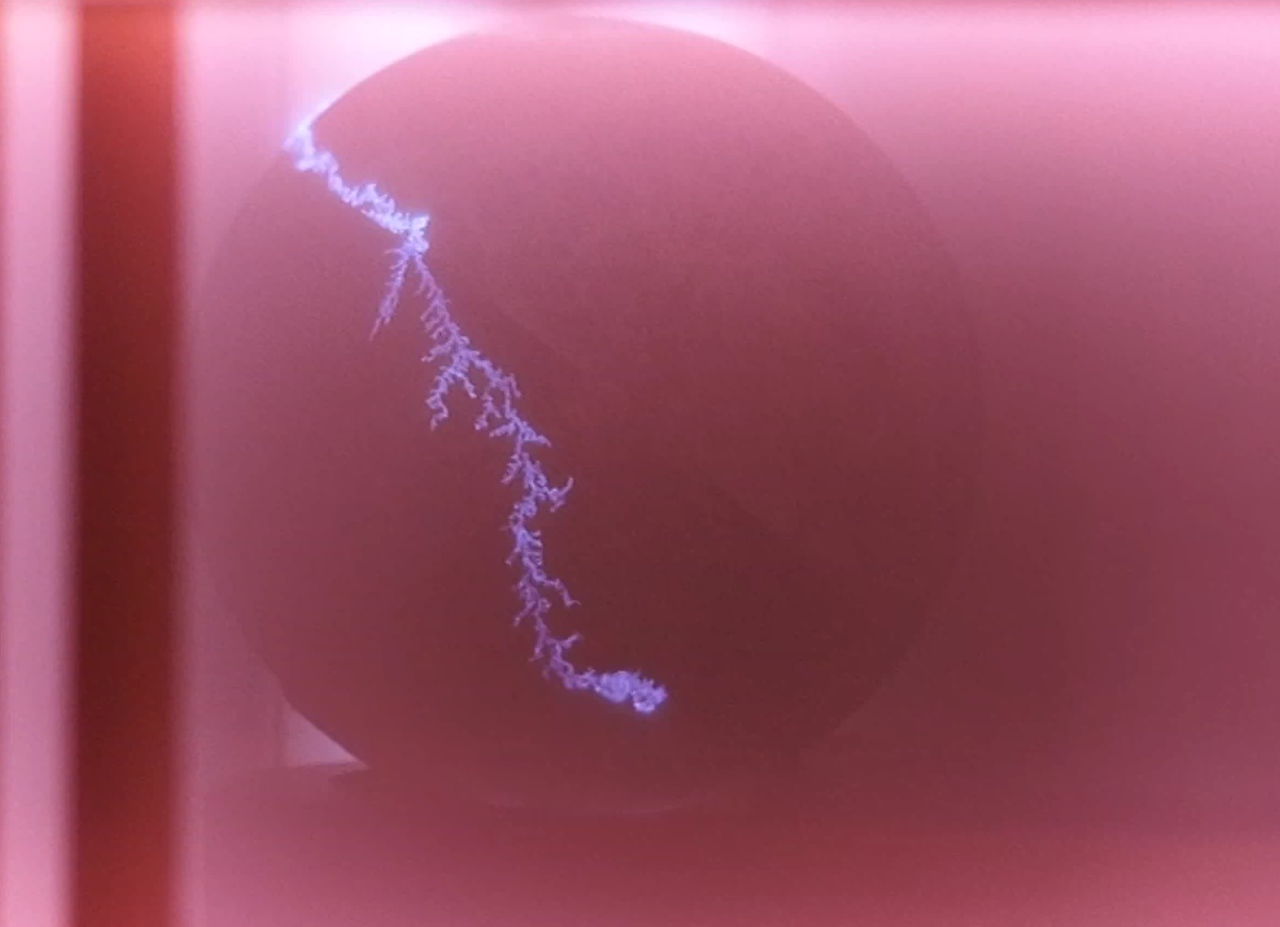

One of the spherical probes during the TiAlN deposition process, showing a severe arcing effect (appearing as lightning bolts) as a result of unneutralised electrical charges distributing over the sphere.

Titanium aluminium nitride (TiAlN) alloys were grown by magnetron sputtering – a highly controlled and repeatable physical vapour deposition process. However, sputter-depositing these coatings on such large spheres proved to be no easy task.

“We dealt with a series of challenges in this project,” said Dr Bakhit. “First of all, the shape and size of the probes were not suitable for common sputtering systems. We used an industrial-scale sputtering system and redesigned the inside of its growth chamber. We came up with a carousel-like structure with two rails that allowed the spheres to freely roll around during the deposition process, leading to uniform coatings.”

“The other unexpected issue was severe arcing that occurred during the growth. To overcome this challenge of unwanted discharge occurring on the surface of the spheres, a special approach with optimised electrical charge density was utilised,” he added.

The RPWI on board the spacecraft is described in detail as part of a paper published in the journal Space Science Reviews. Further details can also be found on the ESA's website for the JUICE scientific community.

Reflecting on the mission, Dr Bakhit said: “I have been involved in several projects in collaboration with partners from both academia and industry. Admittedly, the JUICE mission was the most challenging, but at the same time, the most important and exciting one. It was a great opportunity to contribute to such a large space-related project and I am keen on any life discovery on Jupiter. I am pleased that my contribution was also acknowledged in a prestigious certificate from the ESA.”