New research involving a team of scientists from the University of Cambridge, Rice University and Stanford University, could make bioelectronic devices easier and more reliable to manufacture – all thanks to a chance discovery made during an experiment.

The heat-treated PEDOT:PSS thin film maintained excellent electrical performance when stretched, highlighting its potential for resilient bioelectronic devices both inside and outside the body.

Co-author Margaux Forner

Using a heat-based approach, the scientists were able to streamline the production of a conductive composite material known as PEDOT:PSS, which is widely used in medical implants, computing applications and biosensors.

For more than two decades, scientists working with PEDOT:PSS have used a chemical crosslinker to make the conductive polymer stable in water. But now, new research, published in the journal Advanced Materials, reveals that heating PEDOT:PSS beyond the usual threshold not only makes it stable without needing any crosslinker, but it also creates higher quality devices. Potential applications include neural implants, biosensors and next-generation computing systems.

PEDOT:PSS is a blend of two polymers: one that conducts electronic charge and does not dissolve in water and another that conducts ionic charge and is water-soluble. Because it conducts both types of charges, PEDOT:PSS bridges the gap between living tissue and technology.

The researchers’ new method produces a material with three times higher electrical conductivity and more consistent stability between batches – key advantages for medical applications.

“This method pretty much simplifies a lot of these problems that people have working with PEDOT:PSS,” said co-author Dr Scott Keene from Rice University, and a former postdoc at the Department of Engineering, University of Cambridge. “It also essentially eliminates a potentially toxic chemical.”

The heat-based approach came to light during experiments looking at ways to precisely pattern the material for applications in biomedical optics. Co-first author Siddharth Doshi, a doctoral student at Stanford University, in collaboration with Dr Keene, skipped adding the crosslinker and used a higher temperature while prepping the material. To their surprise, the resulting sample turned out to be stable on its own – with no crosslinker needed.

Co-author Margaux Forner

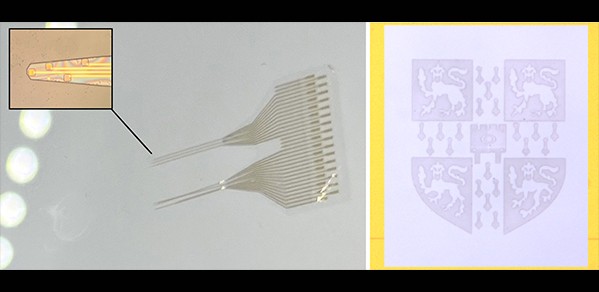

Co-author Margaux Forner, PhD student in the Bioelectronics Laboratory at the Department of Engineering, University of Cambridge, said the heat-treated bioelectronic devices such as transistors, spinal cord stimulators and electrocorticography arrays[1], were easier to fabricate, more reliable and maintained high electrical performance.

“The devices made from heat-treated PEDOT:PSS proved to be robust in chronic in vivo experiments, maintaining stability for more than 20 days post implantation,” she said. “Notably, the PEDOT:PSS thin film maintained excellent electrical performance when stretched, highlighting its potential for resilient bioelectronic devices both inside and outside the body.”

By making PEDOT:PSS more reliable, this discovery could help advance neurotechnology, including implants to restore movement after spinal cord injuries and interfaces that link the brain to external devices.

Beyond simplifying fabrication, the research team found a way to pattern PEDOT:PSS into microscopic 3D structures – a breakthrough that could further improve bioelectronic devices. Using a high-precision femtosecond laser, the researchers can selectively heat sections of the material, creating custom textures that enhance how cells interact with the devices.

“We are really excited about the ability to 3D print the polymers at the microscale,” said Siddharth Doshi. “This has been a major goal for the community, as writing this functional material in 3D could let you interface with the 3D world of biology. Typically, this is done by combining PEDOT:PSS with different photosensitive binders or resins, however, these additions affect the properties of the material or are challenging to scale down to micron-length scales.”

Reference:

Siddharth Doshi., Margaux O. A. Forner et al. ‘Thermal Processing Creates Water-Stable PEDOT:PSS Films for Bioelectronics’. Advanced Materials (2025). DOI: 10.1002/adma.202415827

Adapted from a Rice University press release.

---

[1] Implanted grids or strips of neuroelectrodes used to record brain activity.