Meet Thomas Glenday – an engineer who sits at the helm of the Department’s Design and Technical Services, harnessing the creativity of 75 technicians, each with an eye on engineering precision and cutting-edge technologies.

What I like most about one-off projects such as the reconstruction of the Venn bowling machine is the opportunity to bring engineering to life in a different and slightly more unusual way.

Thomas Glenday

The division is a one-stop shop providing a design and manufacturing service for teaching and research activities, and specialist advice and consultation across University departments.

“Our technicians and design engineers are the lifeblood of this division,” says Thomas, Head of Design and Technical Services. “Without them, we just couldn’t function.”

Equipped with a range of both manual and computer-controlled machinery, the division makes extensive use of Computer Aided Design (CAD), electronics, and design and manufacturing services, along with traditional trades such as carpentry.

Bringing ideas to life

“The technicians are essential to research, teaching and knowledge exchange. They are highly skilled with a diverse range of expertise,” says Thomas, who has a background in manufacturing engineering with knowledge gained in marine, aerospace, and oil and gas sectors.

“Similarly, our design engineers, who work alongside the technicians, can bring ideas to life in any format, be it mechanical, electrical or electronic, from initial concept through to finished product, and all delivered using bespoke equipment and apparatus. The sky’s the limit!”

Of the 75 technicians in the Department, 25 make up the Department’s central manufacturing service and technician hub, which includes the Dyson Centre for Engineering Design – a workspace where students can come together outside of the classroom to think, experiment, design, build and exchange ideas – and the Electrical and Information Engineering Teaching Lab (EIETL).

The remaining 50 technicians are embedded in six academic divisions that function from either the central site at Trumpington Street or from satellite sites at West Cambridge, including the Whittle Laboratory, Institute for Manufacturing (IfM) and the National Research Facility for Infrastructure Sensing (NRFIS).

The six divisions cover:

- Energy, Fluids and Turbomachinery

- Electrical Engineering

- Mechanics, Materials and Design

- Civil Engineering

- Manufacturing and Management

- Information Engineering.

Current projects include (but are not limited to) developing accessibility solutions such as braille tablets; building medical devices such as heart monitors; 3D printing high-performance stainless steels (advanced materials with superior qualities); and trialling innovative materials in aircraft design to help increase flight efficiency.

Thomas Glenday in the workshops at the Department's main site in Trumpington Street. Credit: Charlotte Hester.

Turning back time

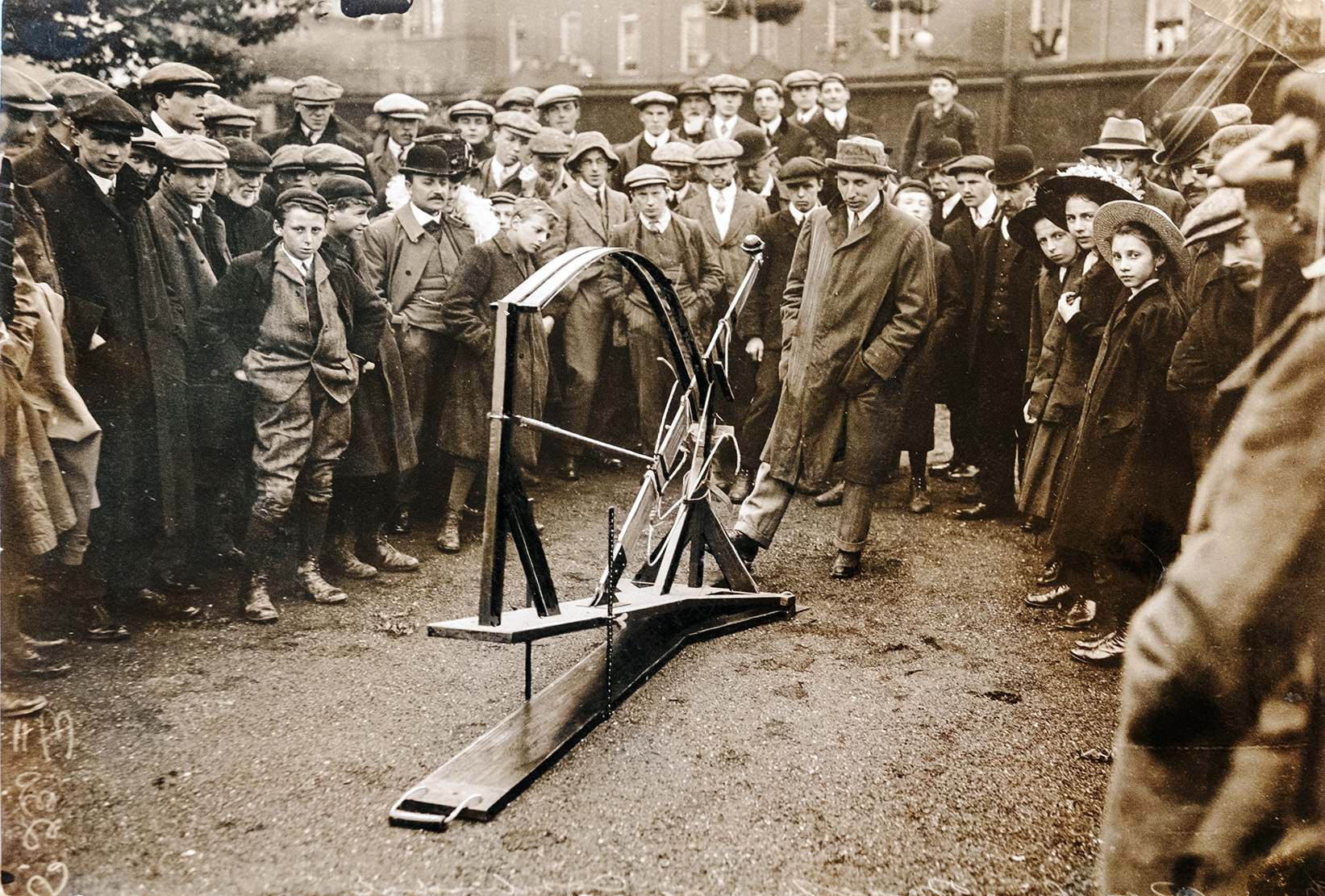

And sometimes a project can literally turn back the clock. Last summer, Thomas was invited to reconstruct a historic bowling machine that bowled out players from the Australian cricket team during a visit to Cambridge more than 100 years ago.

Using patent illustrations and an old photograph discovered online, Thomas and his team brought the 7ft contraption back to life using materials that would have been available at the time such as high-quality hardwood.

The Venn bowling machine propels the cricket ball using a throwing arm powered by elastic rope. But what makes its design special is the ingenuity used to put spin on the ball (the most complicated part of the design) – when the arm travels it pulls a string, which turns a spindle and a bobbin, which in turn spins the ball holder and the ball.

Thomas, who has prior experience in public speaking via media interviews and expert technical debates, was invited to demo the Venn bowling machine at Essex County Cricket Club last summer as part of an educational event. The Essex Year of Numbers initiative was set up to inspire a love of learning, with a focus on numeracy.

“What I like most about one-off projects such as these is the opportunity to bring engineering to life in a different and slightly more unusual way,” says Thomas. “In this case, the reconstruction of the Venn bowling machine has been really fun to work on and it’s an amazing example of what can be achieved with just wood, elastic and maths.”

- Design and Technical Services are available to support teaching apparatus, student and research projects. For design, technical consultation and manufacturing services email design-technical-services@eng.cam.ac.uk

A demo of the Venn bowling machine, circa early 1900s. Pictured, centre, is believed to be John Archibald Venn, the son of the machine’s inventor Dr John Venn. Credit: Professor Yao Liang.