New research led by the University of Cambridge, in collaboration with Hong Kong University of Science and Technology (GZ) and Queen Mary University of London, could redefine how we interact with everyday tools and devices – thanks to a novel method for printing ultra-thin conductive microfibres.

Our approach can help in setting up a sustainable Fibre-of-Things (FoT) future – potentially revolutionising medical diagnostics, treatment, and even creating new forms of wearable technology.

Professor Shery Huang

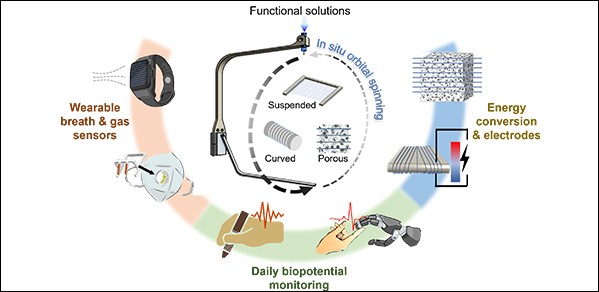

Imagine fibres thinner than a human hair (nano- to micro-scale in diameter) that can be tuned on-demand to add sensing, energy conversion and electronic connectivity capabilities to objects of different shapes and surface textures (such as glass, plastic and leather). This is what the researchers have achieved, including in unconventional materials like porous graphene aerogels, unlocking new possibilities for human-machine interaction in various everyday settings.

The researchers present a one-step adaptive fibre deposition process using 3D printing, set up to satisfy the fast-changing demands of users. The process enables the on-demand deployment of conductive material layers on different surface areas, dependent on the model’s geometry, at the point of use. The findings are reported in the journal Advanced Fiber Materials.

These transparent layers can detect real-time electrocardiogram (ECG) and surface electromyography (sEMG) signals. The researchers demonstrated this function using a robotic hand, a pencil and a plier tool.

Robotic hand

An array of 400 microfibres made of PEDOT:PSS (a conductive polymer), were printed to wrap around the robotic finger. During ECG measurement, a human index finger was pressed against the microfibres of the robotic finger.

“This demonstrates a cost-effective approach to rapidly equip robots with human-interactive sensing functions thanks to PEDOT:PSS microfibre electrodes,” said co-author Stanley Ka, PhD student in the Biointerface Research Group at the Department of Engineering. “Transient electronic skins such as the one demonstrated here are crucial to enable robots and prosthetics to become more human-interactive and mimic the sense of touch.”

The researchers envisage variations of the robotic hand operation, specifically in home care situations.

In a remote care environment, an interactive robot is useful for home-based care or telemedicine (in this case, acting as a remote monitoring device). For the elderly, a robot companion such as this one could periodically check vital signs, including ECG signals, without the use of wearable devices. And in certain crisis situations, where robotic systems such as a robotic arm could be deployed, ECG sensing via a robot could help assess a person’s cardiac status before emergency first responders arrive.

Pencil / handle of a plier tool

To detect sEMG signals from the thumb-tendon area when using a pencil or a plier, an array of PEDOT:PSS microfibres (approximately 600 for the pencil and 1,000 for the plier) were wrapped around the pencil or the plier handle. The human participant was then requested to write with the pencil and cut a rigid object using the pliers, with different levels of force.

Combining the above-mentioned everyday tasks (writing with a pencil and gripping the handle of a plier tool) with real-time biopotential monitoring can alert users or caregivers to abnormal ECG or sEMG patterns. It is useful for monitoring individuals to avoid overexertion or injuries.

For workers using plier tools in hazardous environments (e.g. electrical, chemical or high heat), they too could be monitored for signs of cardiac distress, enabling early intervention in case of fatigue, arrhythmia or other health risks. And in high-risk scenarios where humans and robots work together to move or manipulate objects, ECG and sEMG data gathered from the human could inform the robot’s behaviour e.g. by slowing down if the human shows signs of stress or fatigue.

“These dry microfibre electrodes are long-lasting, and once the sensing task is complete, the fibres can be easily wiped off without damaging or staining the original surfaces of these objects,” said co-author Professor Shery Huang, who leads the Biointerface Research Group.

“Our approach for integrating customisable electronic functions onto various existing objects as shown, can help in setting up a sustainable Fibre-of-Things (FoT) future – potentially revolutionising medical diagnostics, treatment, and even creating new forms of wearable technology.”

Reference:

Ka, S.G.S., Wang, W., Giddens, H. et al. ‘Adaptive Printing of Conductive Microfibers for Seamless Functional Enhancement Across Diverse Surfaces and Shapes’. Advanced Fiber Materials (2025). DOI: 10.1007/s42765-025-00561-6