University of Cambridge spin-out Matta has raised $14 million in funding to transform how products are designed and manufactured.

If we help factories understand themselves we can prevent scrap and rework at the source, delivering a direct, scalable cut to industrial emissions.

Matta Chief Scientist Dr Sebastian Pattinson

Manufacturing underpins a third of global economic output yet remains plagued by inefficiencies that waste up to 20% of production value and raise emissions. Matta, founded on pioneering research from the University of Cambridge’s Institute for Manufacturing (IfM), part of the Department of Engineering, aims to provide a practical route to improving productivity, quality and resilience on today’s shop floor.

Its technology gives factories the ability to see, understand, and improve themselves in real time, understanding any production line within days. It spots defects, traces root causes, and helps teams fix problems before they become costly.

Highly adaptable, Matta can be applied to everything from electronics and automotive to defence and apparel, whether on manual inspection stations, conveyor lines, or robot arms to redefine how products are conceived and created.

It does this by using AI to learn the physical rules of production and apply them on the line. Its first product uses unsupervised and self-supervised computer vision to automate quality control and anomaly detection, perform measurements, diagnose root causes, and recommend corrective actions in real time. A central platform lets teams monitor every camera, analyse results and trace parts across the factory for live visibility of issues and bottlenecks.

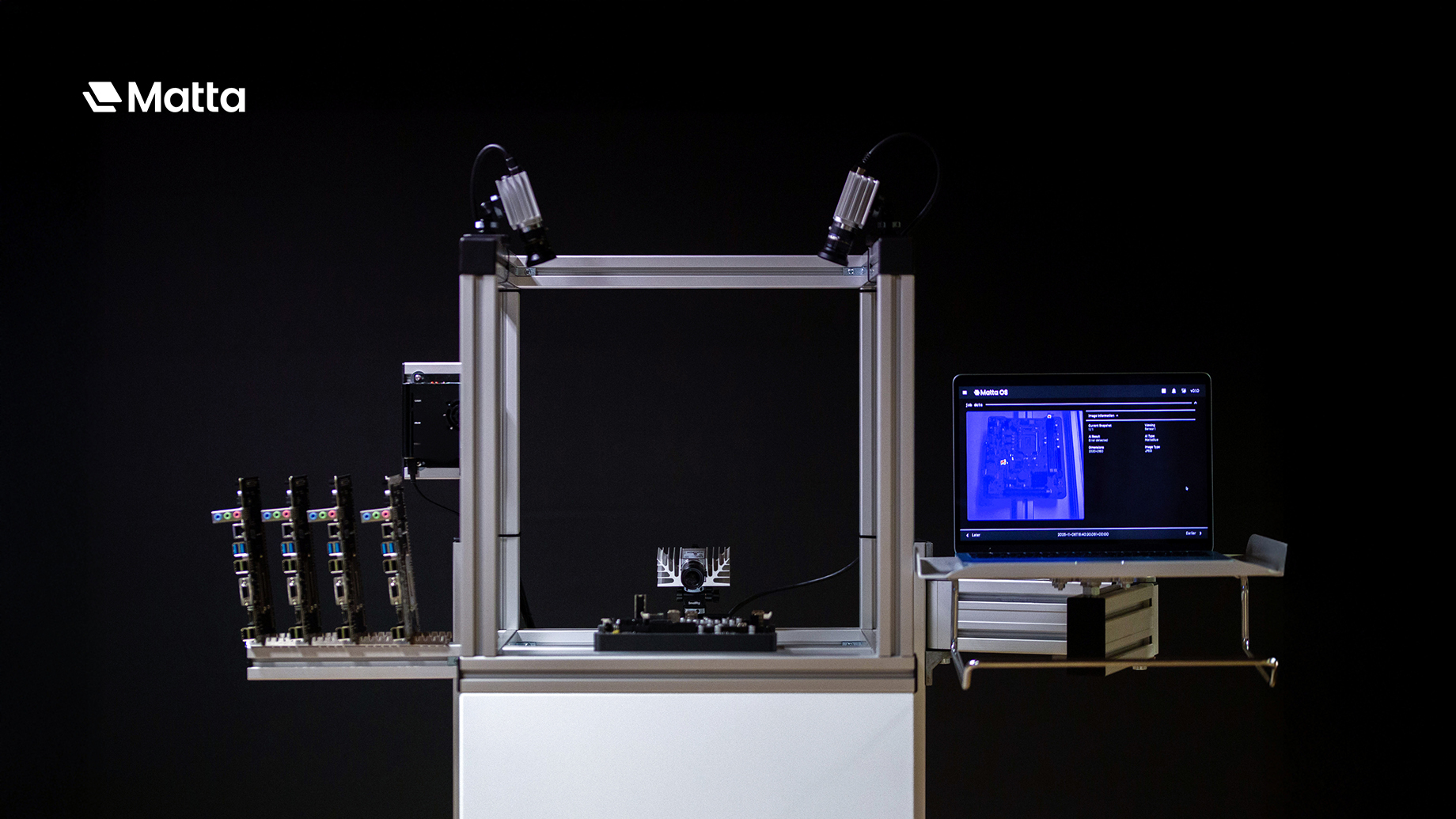

Matta multi-camera AI inspection station checking electronic circuit boards. Credit: Matta

Matta's co-founders Douglas Brion, who completed a PhD in deep learning-enabled control at Cambridge, and Dr Sebastian Pattinson, Associate Professor in Manufacturing Engineering, first met at the IfM. Today, Matta is a fast-growing team with experience from MIT, Imperial, BBC R&D, Google X and Microsoft.

Douglas Brion, co-founder and CEO of Matta, said: “Everything around us is manufactured, from the mug on your desk to the optical cables carrying our Netflix binges. Everyone talks about the glamorous side of manufacturing: generative design, material discovery, Digital Twins, but few spend time on the factory floor. The hard part isn’t dreaming things up inside a computer; it’s making them work at scale. Manufacturing still runs on human know-how, the kind that lets someone on the line kick a machine just right, or run a finger over a scratch, and say, ‘that’s thirty-four microns wide’. We’re using AI to capture and scale that tacit knowledge, so engineers can design things that actually work in the real world. It’s time to manufacture the impossible.”

Dr Pattinson, co-founder and Chief Scientist at Matta, added: "Manufacturing underpins modern living standards, but too much of it still turns materials and energy into waste. If we help factories understand themselves we can prevent scrap and rework at the source, delivering a direct, scalable cut to industrial emissions."

The latest funding will accelerate customer adoption and AI development, expand self-serve deployment, and support Matta’s expansion into key manufacturing regions across Europe and the US, advancing the company’s vision for fully autonomous, end-to-end production.

This article first appeared on the University of Cambridge website and is adapted from a news story published by the Institute for Manufacturing.